知识中心

传感器是怎样生产的?

本页内容更新于2024年10月08日Load cells are integral to weight and force measurement applications across a multitude of industries, serving as critical sensory inputs in automation, process control, commerce, and much more. These devices are pivotal in translating physical forces into actionable data, enabling precise control and measurement in complex systems.

This exploration into load cell manufacturing unveils the depth of expertise and innovation that is required to consistently produce high precision weight and force sensors that can be found in a huge variety of critical systems.

- 1. Introduction to Load Cell Design & Manufacturing

- 2. Design and Pre-production of Load Cells

- 3. Material Input Planning and Purchasing

- 4. Machining of Load Cell Elements

- 5. Heat & Surface Treatment

- 6. Strain Gauge Bonding

- 7. Soldering

- 8. Temperature Compensation

- 9. Encapsulation

- 10. Calibration

1. Introduction to Load Cell Design & Manufacturing

The process of manufacturing load cells combines precision engineering, skilled craftsmanship, detailed oversight, and an uncompromising pursuit of quality. Each load cell, from material selection to final calibration, is a testament to the meticulous attention to detail and dedication to consistency that defines leading manufacturers in this industry.

The current manufacturing process for load cells has evolved greatly since the advent of strain gauge load cells in the 1970s, with ever-greater efficiency, consistency, and performance. Learning how load cells are manufactured can help scale service technicians better diagnose issues, engineers better integrate load cells into systems they are designing, and purchasing managers better coordinate with their load cell supplier.

2. Design and Pre-production of Load Cells

The first phase in creating a load cell involves a detailed design and preproduction process. This is the foundation for manufacturing, where engineers take into account the specific application that the design is intended for, the supplies and capabilities available, the performance targets, past product history, and more to create the design. Advanced CAD tools and Finite Element Analysis (FEA) are often employed to model the load cell’s behaviour under various load conditions, assuring that the final product meets all performance criteria.

Tooling and preproduction, sometimes involving the creation of moulds, dies, jigs, essential for the mass production of load cells must also be prepared. Beyond the hardware, automated processes must be programmed, production instructions documented, and assembly line staff briefed.

3. Material Input Planning and Purchasing

Bills-of-material (BOMs) drafted by the engineering department listing all the materials required for producing a load cell must be executed by the manufacturer’s purchasing department to subcomponent suppliers. Careful maintenance of existing inventory can help to minimize lead times and simplify product consistency. Incoming materials must first be quarantined for QA inspections that ensure that they meet manufacturer specifications before they can be released for production.

4. Machining of Load Cell Elements

|

Load cell elements—the metal body of the load cell—must be machined. Long beams of steel or aluminum must be precisely cut, and CNC-machined to tight tolerances. Certain shapes may require complex programming along with experienced CNC operators. Constant care must be exercised to ensure that load cell elements are machined according to stringent requirements, especially in high-accuracy applications. What can go wrong: When it's done right: |

|

5. Heat & Surface Treatment

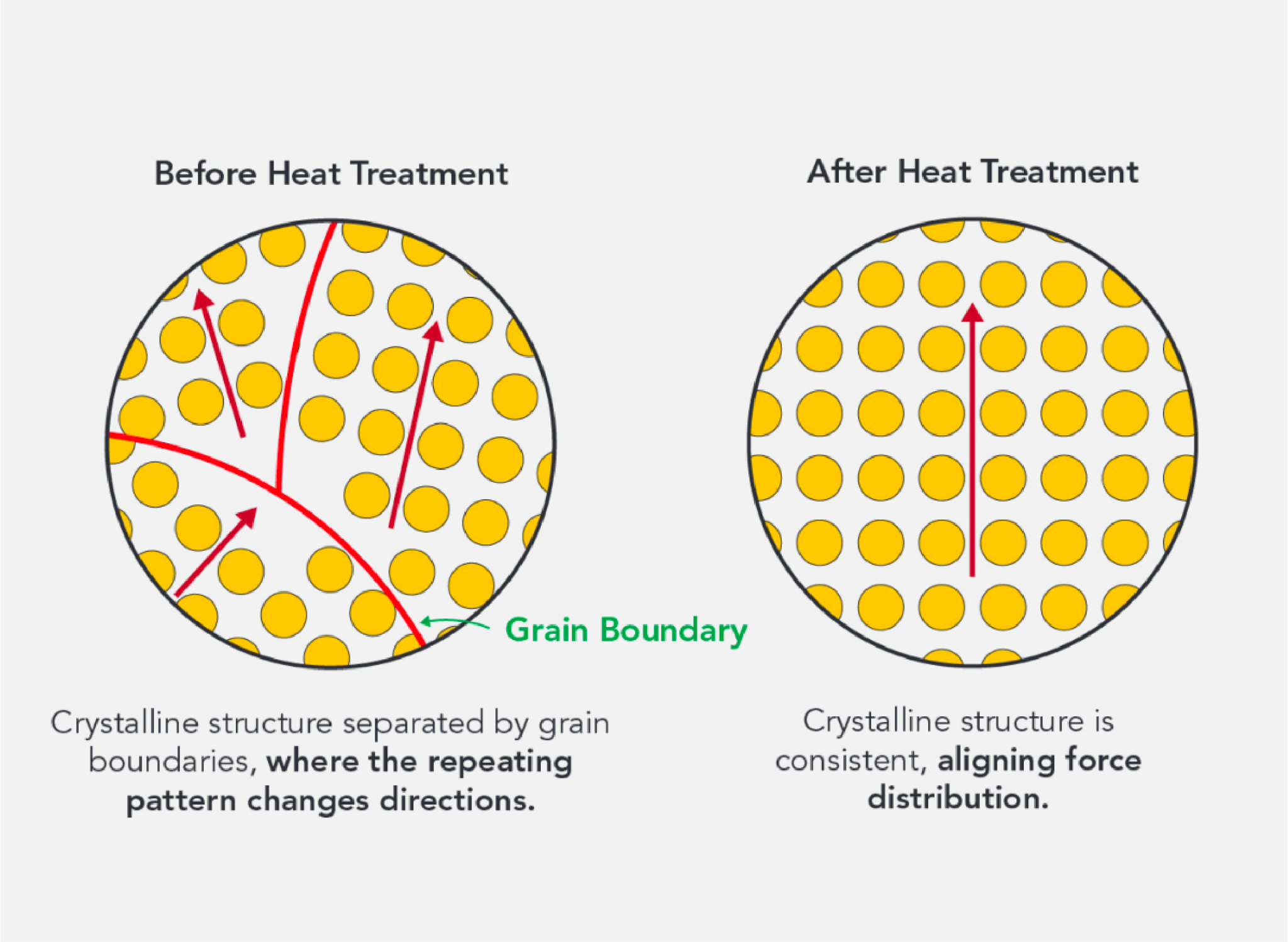

| In the manufacturing process of load cell elements, the stages of forging and machining are crucial but can introduce internal stresses within the material. These stresses, if left unaddressed, can lead to instability and inconsistencies in the load cell’s performance, affecting its accuracy and reliability. To mitigate these issues, heat treatment processes are employed post-machining to relieve these internal stresses. Techniques such as annealing or tempering are commonly used, where the load cell elements are heated to a specific temperature and then cooled under controlled conditions. This process realigns the material’s internal crystalline structure, dissipating stress concentrations and enhancing the overall mechanical properties of the load cell element. In addition to stress relief, surface treatment plays a significant role in extending the lifespan and maintaining the integrity of load cell elements. Corrosion can significantly degrade the performance of load cells, especially those used in harsh environments. Surface treatments such as electroplating, anodizing, or applying corrosion-resistant coatings are effective in creating a protective barrier against corrosive agents. |

|

What can go wrong:

Improper surface treatment, such as reusing old surface treatment chemical solutions, can lead to load cells that corrode faster than expected or specified. Rigorous quality assurance procedures, including audits using specialized corrosion-testing equipment, are necessary to mitigate this risk.

When it's done right:

Load cells from different manufacturers may look the same but can perform very differently over time due to differences in heat and surface treatment. Example: an aluminum load cell with nickel electroplating will last much longer in saltwater environments compared to one without, even as they both visually appear very similarly.

6. Strain Gauge Bonding

|

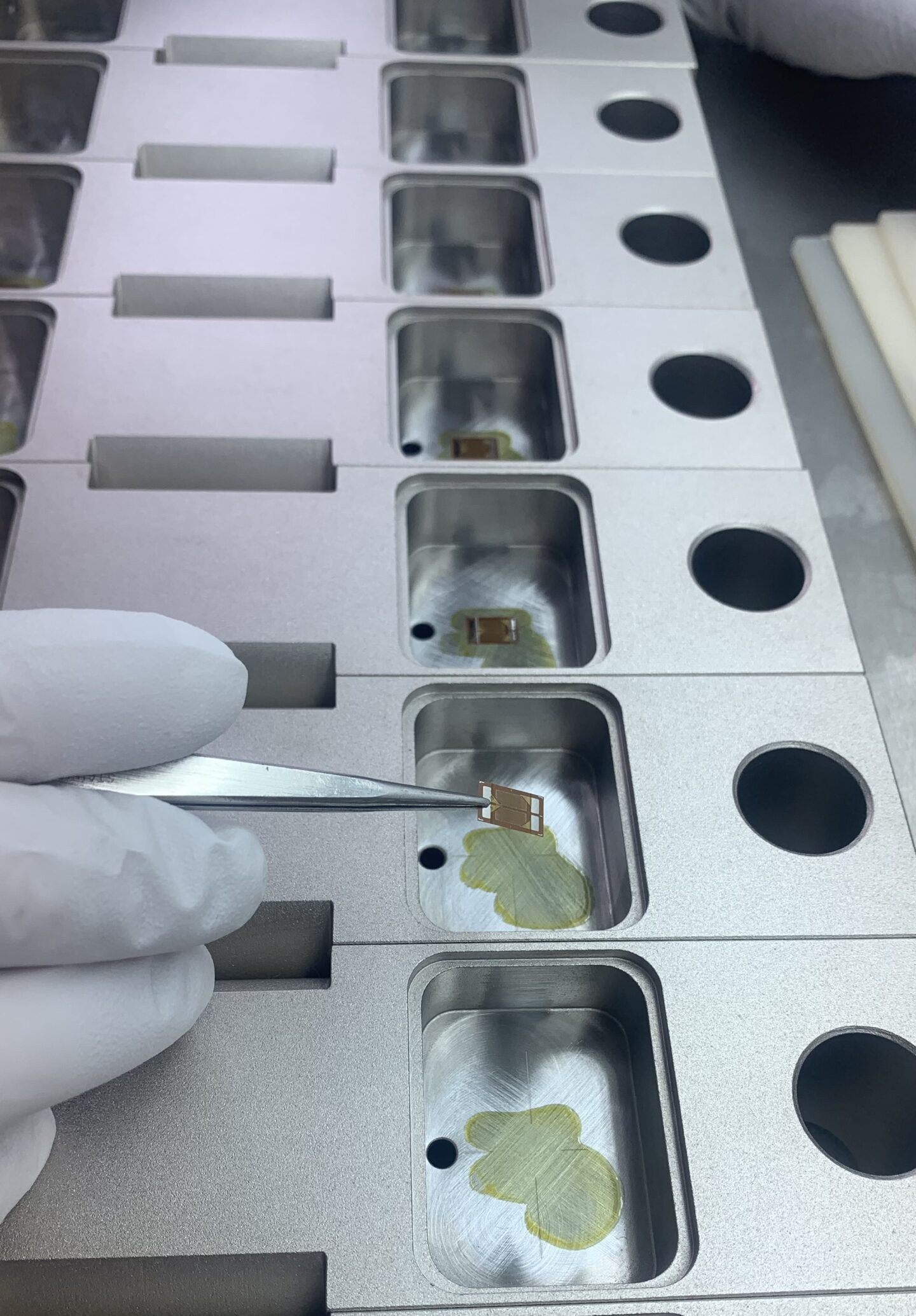

Strain gauges are precisely bonded to cleaned load cell elements at precise locations predefined to maximize load detection. In high-volume production, this may be automated, but this painstaking process is frequently performed manually by skilled assembly line technicians working in a cleanroom. A cleanroom environment helps to prevent particulates that can find its way underneath strain gauges as they are being bonded to the metal element, negatively affecting overall longevity and precision of load cells. After the gauges are bonded by the specialized gauge adhesive, it must undergo a curing process in industrial ovens set to very specific temperatures and timings. This ensures that the gauges is securely bonded and harmonized with the metal in a way that enhances its strain detection performance. What can go wrong: When it's done right: |

|

7. Soldering

|

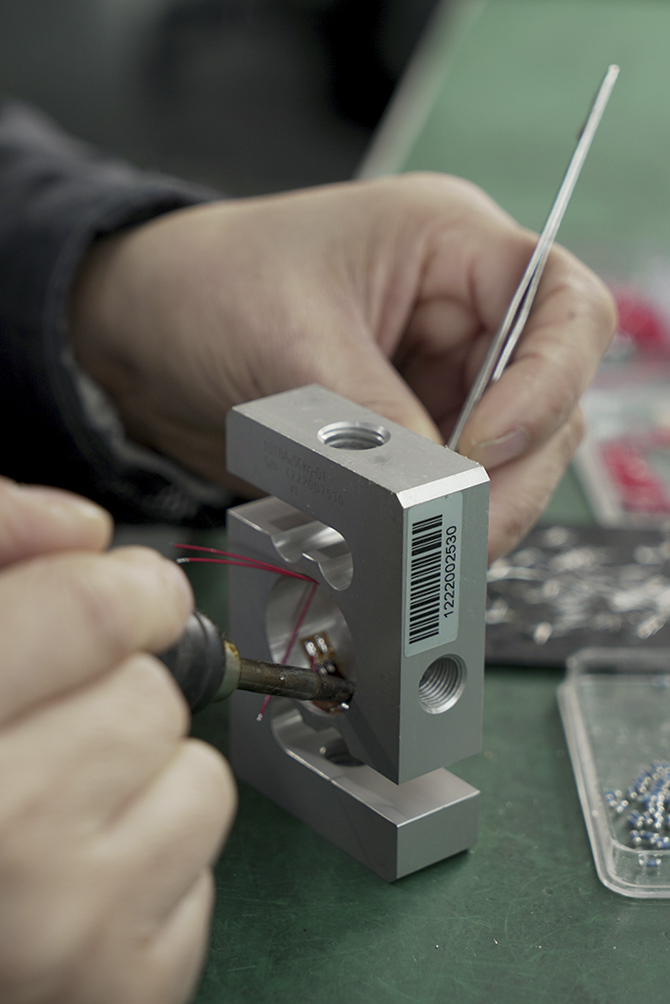

Once securely bonded to the element, the individual strain gauges must be connected together to form a Wheatstone Bridge circuit. This can be another highly delicate process where very small soldering points are connected together by thin wires. As most load cells, except very high volume production runs (>10,000 units minimum), are soldered by hand, this requires skilled workers. An integrated PCB unifies these wires and allows for more complex functions like temperature and zero balance compensation, which are essential to manufacturing high precision load cells. It is also at this stage that other electronics can be integrated, such as chips that can make individual load cells output digital signals rather than its standard analogue output. Did you know that soldering techs regularly need to control their solder points that are 1/3mm² Experience is essential to making quality load cells, and it can take years before a tech is qualified to work on higher complexity load cells. What can go wrong: When it's done right: |

|

8. Temperature Compensation

|

After soldering procedures, load cell are essentially functional products. It can now be tested in specially-built industrial temperature chambers where it is connected to sensory arrays to have its weighing properties monitored as the chamber cycles through hot and cold temperatures. Instruments track the bridge resistances of the load cell, which is fed into data acquisition systems. This allows for each load cell’s individual variation in performance due to temperature fluctuations to be compensated for. Once compensated, it would return to the chamber to verify that each load cell performs within acceptable parameters. To reduce costs, some manufacturers may omit this procedure entirely or choose not to verify the temperature compensation. This can lead to inconsistencies in performance, especially if there are any temperature fluctuations in the application beyond room temperature. |

|

9. Encapsulation

|

To protect the strain gauge and internal circuitry from environmental exposure—moisture, debris, corrosion, external damage—load cells are encapsulated by sealants and laser welding. Generally, an AB potting compound is used to first encapsulate the vulnerable circuitry and strain gauges, filling the internal cavities in which the sensitive electronics are located. Metal encapsulation is then secured to the load cell, covering these cavities, with industrial epoxy or by laser welding. For certain load cell designs, there is a careful balance that must be achieved between protection and performance. Weld sealing a load cell, while offering more robust protection, has the potential to redistribute how loads are directed through the sensor’s intended load-bearing pathways. What can go wrong: When it's done right: |

|

10. Calibration

|

Load cells go through final tests to ensure that each unit produced performs according to defined standards. This includes safety tests like a hi-pot resistance test (for load cells intended for potentially explosive atmospheres) and overload tests to ensure that products can handle moderate overloading without failing. All reputable manufacturers issue individual calibration certificates for each load cell, detailing the specific weighing properties of that unit. This information can be used to facilitate further calibration, legal-for-trade certification, QA, and more. |

|

What can go wrong:

Foregoing calibration processes can reduce costs, but risks critical steps in the quality control process for manufacturing load cells. These tests, beyond simply generating useful data for high precision load cell applications, ensure that each load cell operates at the level it is intended.

When it's done right:

Calibration procedures ensure that load cells perform according to expectations out-of-the-box, reducing the need for additional adjustments and fine tuning. These procedures serve as a final test for each load cell, and generates a calibration certificate.